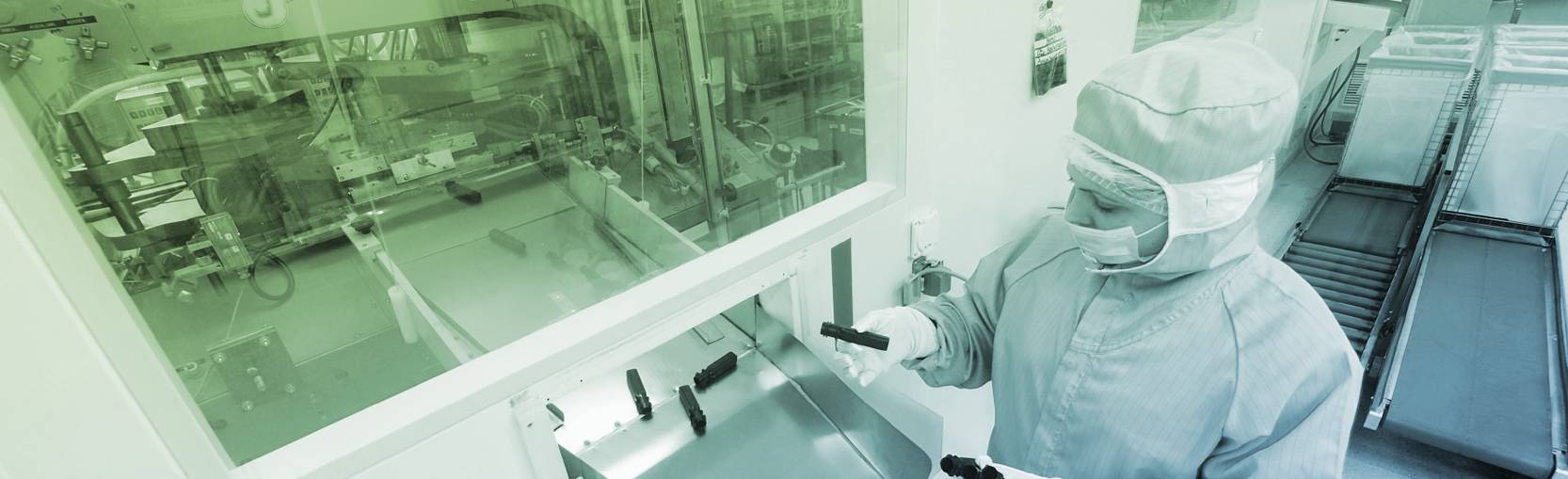

Clean Room

In today`s world the cleanroom production is of great importance, espacially when it comes to creating pharmaceutical products. We produce these in dust proof or completly isolated production areas meeting the standards of ISO 7 air purity class according to ISO 14644-1. The clean room is tested and certified annually by an authorized company. The system reaches the air purity class ISO 7 in operation according to ISO 14644-1.

In order to keep up with the increasing international requirements, the newly certified ISO 15378 and the high requirements of the customers, Kunststoff-Packungen AG decided to produce some products of the injection blow moulding production in clean room conditions.

To complete the task of the classification of all requirements for indoor air, media quality, for the design of a location and the invesment part, we added a competent partner in the clean room industry. In an extremly close and constructive cooperation the requirements for the clean room system were defined.

After intensive discussions, operaters and quality assurance decided to place the injection blow moulding machine in a satellite manner around the process room.

As a result, it became necassary to create a separate mini-enviroment for each injection blow moulding machine, to protect the products. It became manditory to seperate the entry into the process room, incoming FDA-compliant overpresure ratios. In the end, each machine recieived a tailor-made suit.

This concept offered the oppotunity to guide the pure air, which escapes from the overpressured process room, intentionally over the parts in the counter-current principle. The enviroment has been designed to achieve a minimumflow rate of 0.30 m/s at the critical point of risk. The indoor air Quality specified by EU-GMP class C (10,000) and ISO 7 according to ISO 14644-1 was significantly undercut. In short time span we have succeeded in setting up a facility that reflects the latest state of clean room technology in all aspects.

Key Figures

- Process room 47m2 / 150m2

- Handling room 19m2

- Material lock 4.4m2

- Personal lock 4m2 / 10m2

- Air volume ~ 6000 m3/h

- Air change rate > 40 / >90

- Overpressure Process room/Hall 35 Pa / 30 Pa

- Air-conditioned to 23° Celsius